The field of surgical robotics has witnessed remarkable advancements in recent years, with material innovation playing a pivotal role in enhancing performance. Among the critical challenges in designing these sophisticated machines is vibration damping—a factor that directly impacts precision during delicate procedures. Engineers are now exploring novel material compositions and structural designs to minimize unwanted oscillations without compromising the robot's agility or sterility requirements.

Traditional surgical robots often relied on rigid metallic frameworks, which provided stability but transmitted vibrations from motors and external forces. This created a paradox: the very materials meant to ensure precision sometimes introduced microscopic tremors that could affect suturing or cutting accuracy. The latest generation of systems addresses this through viscoelastic composites that absorb vibrational energy while maintaining the necessary stiffness for controlled movements.

Polymer-metal hybrid structures have emerged as particularly promising solutions. These combine the dampening properties of specialized polymers with the load-bearing capacity of surgical-grade alloys. During testing, prototypes featuring gradient-density polymer inserts between titanium joints demonstrated up to 40% reduction in tooltip vibration compared to conventional designs. The polymers undergo careful formulation to meet medical standards for biocompatibility and resistance to repeated sterilization cycles.

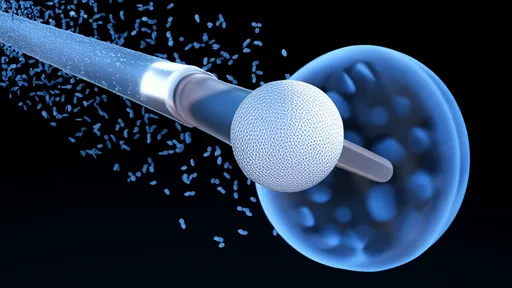

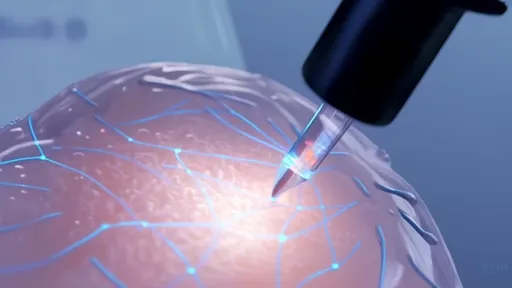

Another breakthrough involves cellular material architectures inspired by bone microstructure. By engineering microscopic air pockets within the robot's structural components, researchers create natural vibration-dampening pathways. This biomimetic approach not only reduces weight but also dissipates harmonic vibrations that could interfere with sensitive force-feedback systems. Early clinical trials show these materials help maintain sub-millimeter accuracy even during prolonged procedures.

The integration of smart materials represents perhaps the most revolutionary development. Shape-memory alloys and piezoelectric elements are being embedded within robotic arms to actively counteract vibrations in real-time. These materials function as both sensors and actuators—detecting minute oscillations through changes in electrical resistance and automatically adjusting their stiffness to neutralize disturbances. Such systems operate continuously without the latency issues associated with traditional electronic feedback loops.

Material scientists emphasize that successful vibration control requires holistic design philosophy. Beyond individual components, attention must focus on how different materials interact across the entire kinematic chain. Advanced simulation tools now allow engineers to model vibrational modes across multiple frequencies, optimizing material selection for each robotic segment. This systems-level approach has yielded robots where vibrations attenuate exponentially from base to end-effector.

Sterilization compatibility remains a non-negotiable constraint that shapes material choices. Autoclave-resistant elastomers and ceramics have become essential in joints and grippers, where both movement precision and microbial safety are paramount. Recent innovations in surface treatments allow porous dampening materials to maintain their vibration-absorbing properties while becoming completely impervious to bacterial penetration—a critical requirement for repeated surgical use.

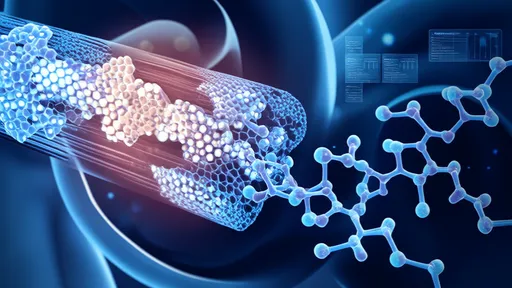

The future trajectory points toward self-adapting material systems that modify their dampening characteristics based on procedure type. Imagine robotic instruments that subtly alter their molecular structure when switching from bone drilling to microvascular anastomosis. Such context-aware material behavior could emerge from advances in metamaterials and nanotechnology, potentially redefining what's possible in robotic-assisted surgery.

As these technologies mature, regulatory bodies face new challenges in evaluating material safety and performance. Traditional certification processes struggle to keep pace with composite materials exhibiting dynamic properties. The industry is responding with novel testing protocols that assess not just static biocompatibility but also long-term material behavior under cyclical stresses typical of surgical environments.

Surgeons working with next-generation systems report tangible differences in operative feel. The absence of high-frequency vibrations allows for more confident movements during microscopic procedures, particularly in specialties like ophthalmology or neurosurgery. This sensory improvement, enabled by material science, may prove as significant as the robots' mechanical precision in driving wider clinical adoption.

Looking ahead, the convergence of material science and robotics promises to overcome one of the last barriers to truly human-like surgical dexterity. As vibration becomes a controlled variable rather than an engineering constraint, robotic systems may achieve levels of precision surpassing even the steadiest human hands—all through the intelligent application of advanced materials designed to move with purpose and stop with certainty.

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025

By /Jul 21, 2025